Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Three Commonly Used Modified Engineering Plastics in Automotive Manufacturing

Introduction:

In recent years, the automotive manufacturing industry has witnessed a significant shift towards the adoption of modified engineering plastics over traditional metal materials. This transition aims to achieve lightweighting and enhance overall vehicle fuel efficiency and environmental sustainability. Among the plethora of modified engineering plastics available, three stand out as particularly prominent within the industry: polypropylene (PP), polyamide (PA), and polycarbonate/acrylonitrile-butadiene-styrene alloy (PC/ABS).

Polypropylene (PP)

https://www.toponew.com/products/pp-compound

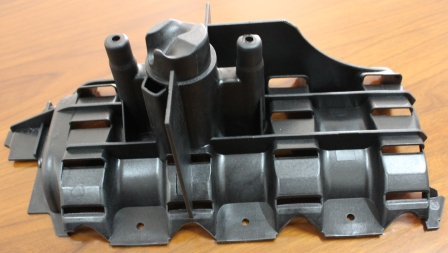

Polypropylene (PP) is hailed as one of the lightest plastics, boasting a density ranging from 0.89 to 0.91 g/cm3. Its semi-crystalline structure offers high strength, rigidity, chemical resistance, excellent electrical properties, and processing capabilities. PP's versatility extends to various modification methods, including copolymerization, cross-linking, filling, and reinforcement. This flexibility, coupled with its favorable price-performance ratio, renders PP an ideal material for automotive lightweighting initiatives. In fact, PP accounts for a substantial portion of the total plastic usage in vehicles, with applications spanning bumper assemblies, dashboards, door panels, and air conditioning components.

Polyamide (PA)

https://www.toponew.com/products/pa66-compound

Polyamide (PA) represents another cornerstone in automotive engineering plastics. Renowned for its exceptional mechanical properties, solvent resistance, chemical and oil resistance, weather durability, and ease of processing, PA finds extensive utilization in automotive, electrical, and specialized equipment sectors. Variants such as PA6 and PA66 dominate the automotive PA landscape, comprising over half of global PA usage within the automotive domain.

Polycarbonate/acrylonitrile-butadiene-styrene alloy (PC/ABS)

https://www.toponew.com/products/pc-abs-alloy

Polycarbonate/acrylonitrile-butadiene-styrene alloy (PC/ABS) combines the superior impact strength and high heat resistance of polycarbonate with the excellent processing performance, weather resistance, and chemical durability of ABS. This hybrid material lends itself well to injection molding, extrusion, and compression molding processes, making it an ideal choice for manufacturing automotive interior and exterior components, as well as electrical and electronic elements.

Conclusion

These three modified engineering plastics not only contribute to vehicle lightweighting and enhanced fuel efficiency but also fulfill automotive requirements for safety, comfort, and aesthetics. As technology continues to advance, the automotive industry's demand for modified engineering plastics is expected to rise, ushering in a new era of innovative automotive plastic materials.

At TOPONEW, we are committed to providing cutting-edge insights and solutions to meet the evolving needs of the automotive manufacturing sector.