Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

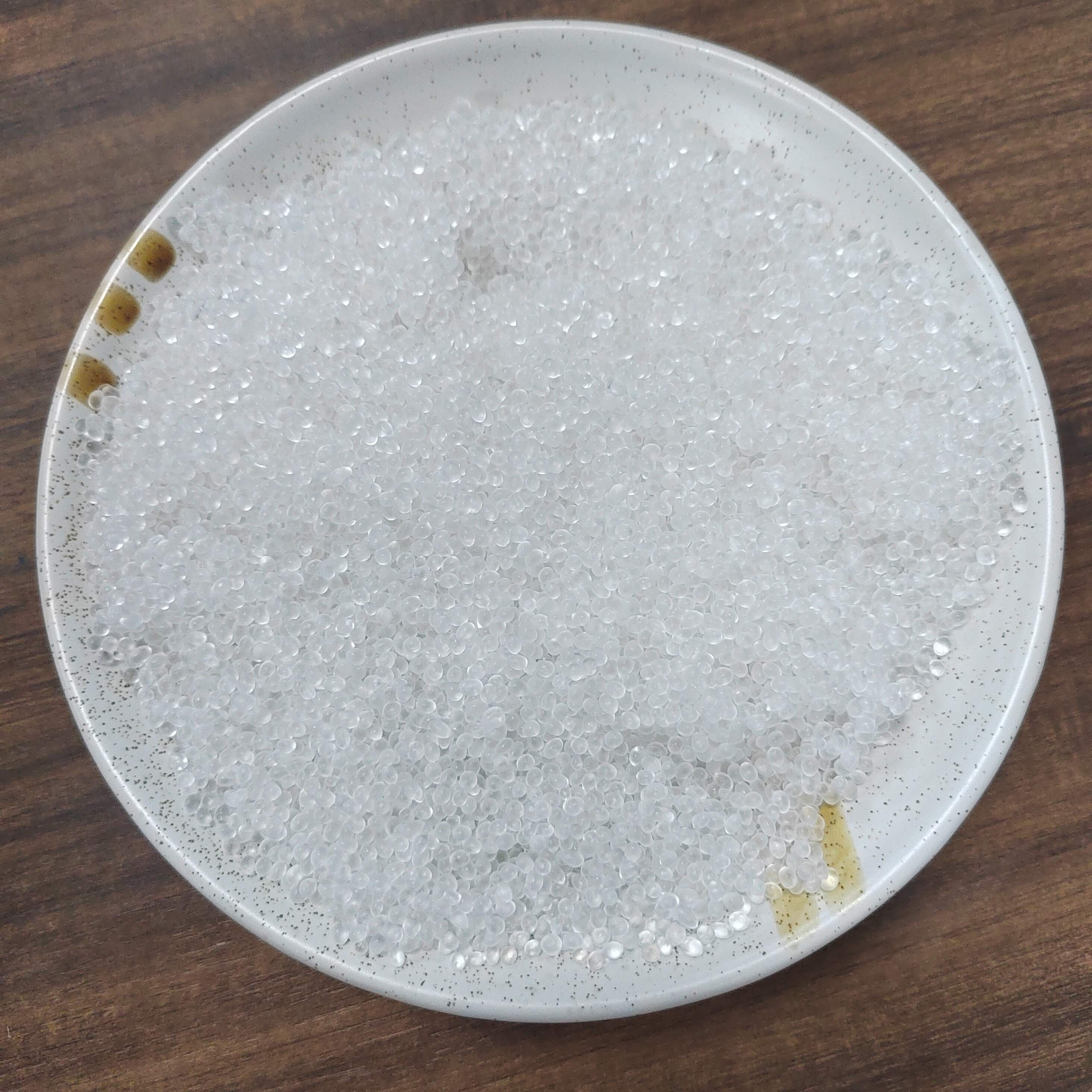

Thermoplastic Polyurethane (TPU) Elastomer

1. Material Overview

Thermoplastic Polyurethane Elastomer (TPU) is a class of linear polymeric materials synthesized through a stepwise polymerization of diisocyanates, polyols, and chain extenders. TPU combines the high elasticity of rubber with the processability of thermoplastics. It features a reversible physical cross-linking structure, allowing repeated melt processing and reshaping.

At the molecular level, TPU consists of hard segments and soft segments. Hard segments, formed by diisocyanates and chain extenders, provide rigidity and strength, while soft segments, composed of polyether or polyester polyols, provide flexibility and elasticity. By adjusting the ratio and chemical structure of these segments, TPU’s hardness, elastic modulus, wear resistance, and chemical stability can be precisely controlled for customized performance.

2. Key Performance Characteristics

Mechanical Properties

TPU exhibits excellent mechanical strength, with tensile strength typically ranging from 30–60 MPa, elongation at break between 400–800%, and tear strength up to 80–100 kN/m, demonstrating outstanding toughness and impact resistance.

Abrasion and Fatigue Resistance

With a low surface friction coefficient, TPU has abrasion resistance about five times higher than natural rubber and maintains superior fatigue resistance under high-frequency bending and dynamic loading.

Oil, Chemical, and Weather Resistance

TPU resists mineral oils, fatty oils, oxidizers, ozone, and many organic solvents. Polyether-based TPUs show excellent hydrolysis and microbial resistance, suitable for humid or outdoor environments.

Wide Temperature Range

TPU maintains stable elasticity from −40 °C to 120 °C. Specially modified grades can extend the working range from −60 °C to 150 °C, enabling use in extreme conditions.

Recyclability and Environmental Friendliness

As a thermoplastic material, TPU can be recycled and reprocessed. It is free of plasticizers and halogens and does not release toxic gases when burned, meeting RoHS and REACH standards.

3. Processing Methods and Equipment Requirements

TPU’s thermoplasticity allows for various processing methods:

-

Injection Molding: Suitable for precise components such as shoe soles, seals, and structural parts; typical processing temperature: 180–230 °C.

-

Extrusion: For hoses, cable sheaths, and films; melt temperature gradients must be controlled to prevent bubbles or degradation.

-

Casting and Blown Film: Produces highly transparent and abrasion-resistant films for protective and packaging applications.

-

Spinning and 3D Printing: Melt-spun TPU forms elastic fibers. TPU shows excellent interlayer adhesion and flexibility in FDM and SLS 3D printing.

4. Typical Application Fields

-

Footwear Industry: Midsoles, air cushions, and upper films combining elasticity and durability.

-

Automotive Manufacturing: Dashboards, hoses, seals, and overmolded components for enhanced comfort and durability.

-

Electronics and Communications: Cable sheaths, phone cases, wearable device straps with soft touch and high bend resistance.

-

Industrial Components: Gears, conveyor belts, rollers, and seals, replacing rubber for longer service life.

-

Medical Devices: Catheters, syringe components, and flexible joints compliant with ISO 10993 biocompatibility standards.

5. Future Development Trends

Key TPU development directions include:

-

Bio-based TPU: Using renewable polyols such as poly(butylene succinate) or castor oil derivatives to reduce carbon footprint.

-

Recycled TPU Systems: Mechanical recycling or chemical depolymerization to promote circular material usage.

-

Functional Modifications: Conductive, flame-retardant, antistatic, and antibacterial TPUs are emerging to meet electronics and medical needs.

-

Advanced Applications: TPU shows great potential in 3D printing, smart wearables, and flexible robotics components.

6. Conclusion

TPU elastomer, with excellent mechanical properties, chemical stability, and environmental friendliness, has become a key material in engineering plastics. Through molecular design and modification, its application scope continues to expand. TPU serves as a critical bridge between flexible materials and high-performance engineering plastics, supporting advancements in material science and intelligent manufacturing for sustainable development.