Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

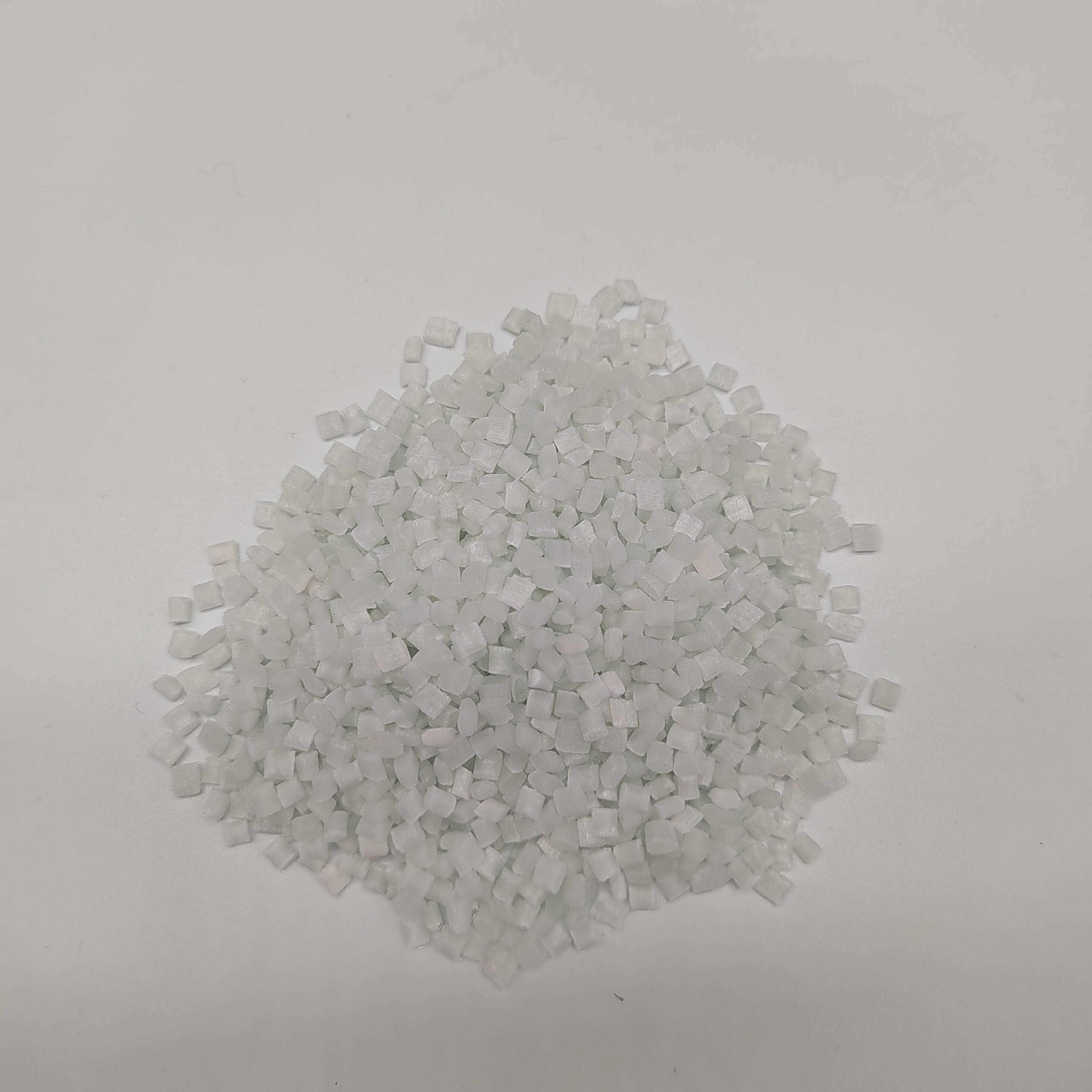

PP Materials with Fiber Reinforcement

Polypropylene (PP) is a widely used thermoplastic resin known for its low density, excellent chemical resistance, and good processability. However, its rigidity, heat resistance, and dimensional stability are relatively limited. To overcome these shortcomings, reinforced PP materials such as glass fiber reinforced PP and carbon fiber reinforced PP are commonly developed.

1. Glass Fiber Reinforced PP (PP GF)

By incorporating short glass fibers (typically 10–50%) into the PP matrix, the material’s rigidity, strength, and heat resistance are significantly improved.

-

Key Features:

-

Higher tensile and flexural strength

-

Improved heat distortion temperature

-

Enhanced dimensional stability and creep resistance

-

-

Applications: Automotive parts, appliance housings, structural components, pipe fittings, etc.

2. Carbon Fiber Reinforced PP (PP CF)

Carbon fiber reinforcement provides PP with lighter weight and superior mechanical properties compared to glass fiber. In addition, carbon fiber gives PP certain electrical conductivity.

-

Key Features:

-

High specific strength and modulus

-

Lower density for weight reduction

-

Excellent dimensional stability and fatigue resistance

-

Conductive/anti-static properties (depending on formulation)

-

-

Applications: Lightweight automotive parts, sports equipment, electrical components, industrial structural parts, etc.

3. Other Reinforcement Options

Besides glass fiber and carbon fiber, PP can also be modified with other fillers or combined reinforcement:

-

Mineral Reinforced PP: Talc, mica, etc., for improved rigidity, heat resistance, and reduced shrinkage.

-

Hybrid Reinforcement: Glass fiber + mineral, or glass fiber + carbon fiber, to balance cost and performance.

-

Functional Enhancement: Flame retardant, weather resistant, or impact modified PP grades for specific requirements.

4. Conclusion

Reinforced PP materials retain polypropylene’s excellent processability and chemical resistance while significantly improving its mechanical strength, thermal resistance, and dimensional stability. With tailored reinforcement solutions, PP compounds are widely used across automotive, appliances, electronics, construction, and industrial applications.