Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Comprehensive Guide to PA6 / PA66 Filament Extrusion Applications

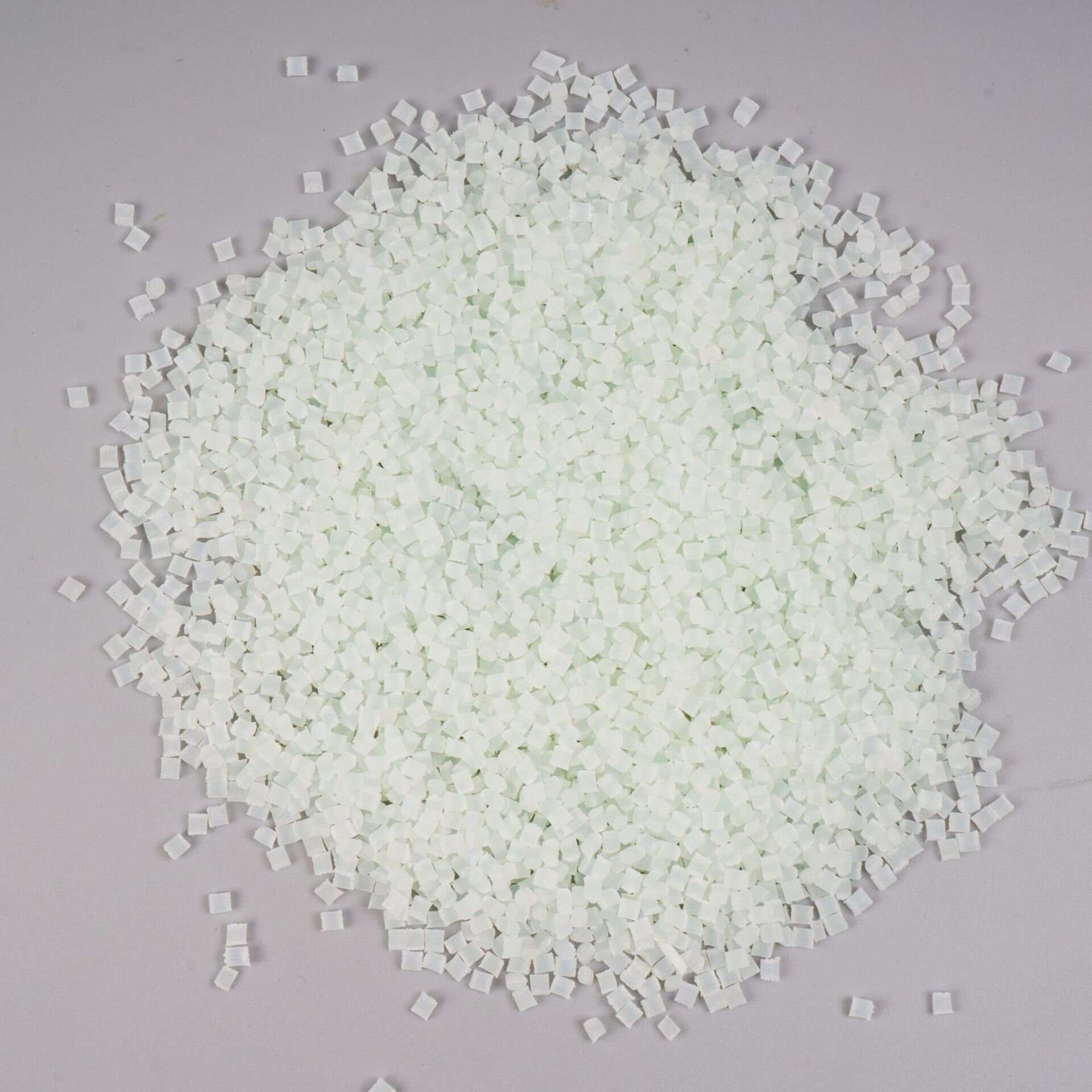

In the plastics industry, nylon (PA) is one of the most widely used engineering materials, especially in filament extrusion. Among the nylon family, PA6 and PA66 are the two most common grades. Thanks to their excellent mechanical strength, abrasion resistance, and smooth surface finish, they are widely used in fishing nets, brush bristles, sewing threads, industrial yarns, filtration meshes, and even 3D printing filaments.

This article provides an in-depth look at the properties of PA6 and PA66, their filament extrusion process, and the main application fields.

1. Properties of PA6 and PA66

PA6 (Polyamide 6)

-

Advantages: Good toughness, high knot strength, excellent abrasion resistance, easy to process.

-

Limitations: Higher moisture absorption, less dimensional stability compared to PA66.

-

Typical Use: Products requiring flexibility, such as fishing nets, standard brush bristles, and regular sewing threads.

PA66 (Polyamide 66)

-

Advantages: Higher mechanical strength, better heat resistance, improved fatigue and wear resistance compared to PA6.

-

Limitations: Requires higher processing temperature, relatively higher cost.

-

Typical Use: High-strength and high-durability applications, such as industrial sewing yarns, sports strings, filtration meshes, and 3D printing materials.

2. Filament Extrusion Process

-

Raw Material Drying

Nylon absorbs moisture easily. Before extrusion, PA6/PA66 must be dried thoroughly, usually below 0.1% moisture content. -

Melt Extrusion

The polymer is melted and extruded through a spinneret to form continuous filaments. -

Cooling and Solidification

Filaments are cooled by water or air to stabilize their shape and dimensions. -

Drawing and Orientation

Multi-stage drawing aligns the molecular chains, increasing crystallinity, strength, and abrasion resistance. -

Winding & Post-Treatment

The finished filaments are wound onto spools. Some applications require additional steps such as coloring, coating, or functional finishing.

3. Major Applications of PA6/PA66 Filaments

1) Fishing Nets & Fishing Lines

-

PA6: Flexible with high knot strength, ideal for fishing nets.

-

PA66: More abrasion resistant, suitable for premium fishing lines and long-lasting nets.

2) Brush Bristles

-

Consumer Brushes: Toothbrushes, cleaning brushes, cosmetic brushes.

-

Industrial Brushes: Polishing brushes, grinding brushes, road-sweeping brushes.

-

Material Choice: PA6 bristles are softer, while PA66 bristles are stiffer and more wear-resistant, making them ideal for high-end or industrial use.

3) Sewing Threads & Industrial Yarns

-

Garment Sewing Threads: Strong, durable, and less prone to breakage.

-

Industrial Yarns: Used in safety belts, protective ropes, and parachute cords.

-

Material Choice: PA66 is preferred for high-strength, heat-resistant applications.

4) Filtration Meshes

-

PA6: Commonly used in household air filters and water filtration.

-

PA66: Suitable for industrial filtration, chemical resistance, and high-temperature environments.

5) 3D Printing Filaments

-

PA6/PA66 filaments are widely used in FDM 3D printing, offering toughness and impact resistance.

-

Typical applications include automotive parts, tool housings, and sports equipment components.

6) Sports & Leisure Products

-

Racket Strings: Tennis and badminton racket strings require high strength and durability, making PA66 the preferred choice.

-

Other Uses: Fishing lines, kite strings, climbing ropes.

7) Medical & Specialty Applications

-

Surgical Sutures (with modified nylon grades).

-

Military & Aerospace Ropes: High strength and durability under extreme conditions.

4. Conclusion

PA6 and PA66 filaments are versatile materials with broad applications:

-

PA6: More flexible and cost-effective, suitable for fishing nets, standard bristles, and general-purpose ropes.

-

PA66: Stronger, more durable, and heat-resistant, ideal for industrial yarns, high-performance bristles, racket strings, and engineering-grade 3D printing.

When choosing between PA6 and PA66, manufacturers should balance mechanical performance, flexibility, abrasion resistance, and cost based on the end-use requirements.

Looking ahead, PA6 and PA66 filaments will continue to evolve toward modified, composite, and eco-friendly solutions, opening new opportunities across industries.