Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Exploring the Pros and Cons of Glass Fiber-Reinforced Nylon

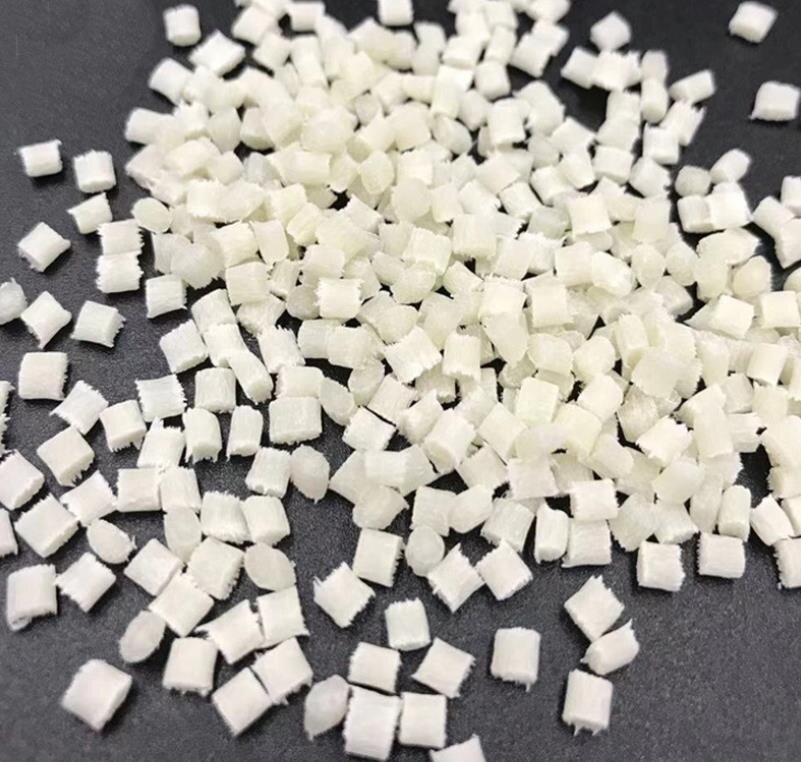

We are TOPONEW, a manufacturer specializing in the production of modified plastic pellets. Our expertise lies in crafting modified plastic pellets tailored to various applications. Among our offerings, we provide materials filled with 10%-50% glass fiber content. While glass fiber-reinforced nylon enhances the performance of nylon products, it's essential to acknowledge the accompanying drawbacks that require careful consideration.

PA66 GF20/ PA66 GF30/ PA66 GF35/ PA66 GF40/ PA66 GF50

Advantages of GF Reinforced Nylon Material

Enhanced strength and rigidity of nylon:

By adding glass fibers, the strength and rigidity of nylon are significantly improved, enabling it to better withstand heavy loads and resist deformation. This enhancement is mainly attributed to the strength and modulus of the glass fibers.

Improved heat stability:

Glass fibers can enhance the heat stability of nylon, making it less prone to deformation and decomposition at high temperatures. This high-temperature stability makes reinforced nylon an ideal choice for some high-temperature applications, such as automotive and aerospace industries.

Enhanced wear resistance:

Adding glass fibers can improve the wear resistance of nylon, making it more durable under friction and wear conditions. This characteristic is crucial for applications that require resistance to friction and wear, such as bearings and gears.

Reduced shrinkage and warpage:

The addition of glass fibers helps to reduce the shrinkage and warpage of nylon, improving dimensional stability and accuracy. This is beneficial for manufacturing precise parts and reducing the need for post-molding adjustments.

Cost reduction:

Although glass fibers are relatively expensive, they may reduce overall costs as they can replace some nylon resins. Additionally, due to the lower density of glass fibers, the weight of the products can be reduced, further lowering transportation and logistics costs.

Disadvantages of GF Reinforced Nylon Material

Increased surface roughness:

The addition of glass fibers increases the surface roughness of reinforced nylon, which may require additional post-processing or coatings to improve surface smoothness.

Increased processing difficulty:

The rigidity and length of glass fibers may cause wear or damage to processing equipment, requiring the use of special tools and molds. Additionally, precise control of processing parameters is needed to ensure good dispersion and uniformity.

Inconsistent elastic modulus:

Non-uniform dispersion of glass fibers in the nylon matrix may result in inconsistencies in the material's elastic modulus. This could affect the material's performance and reliability.

Increased moisture absorption:

Reinforced nylon may have higher moisture absorption compared to pure nylon. This could affect the material's performance and dimensional stability, especially in humid environments.

Higher cost:

Although glass fibers can reduce overall costs, their price remains relatively high. This may limit their use in some cost-sensitive applications. Environmental impact: Glass fibers are not biodegradable and may have some environmental impact. In terms of sustainability and environmental protection, the advantages and disadvantages need to be balanced.

Health risks:

Glass fibers may pose certain health risks to human health, such as inhalation or ingestion, and long-term exposure may cause damage to organs such as the lungs. Therefore, appropriate occupational health measures need to be taken during use.