Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Technical Overview of Flame Retardant ABS: Performance, Applications, and Selection Guide

With increasing safety regulations and fire protection requirements in electronics, automotive, and household appliance industries, Flame Retardant ABS (Acrylonitrile Butadiene Styrene) has become a crucial material for structural and functional components. Compared to standard ABS, flame retardant ABS maintains excellent mechanical and processing properties while providing enhanced fire resistance, ensuring product safety and regulatory compliance.

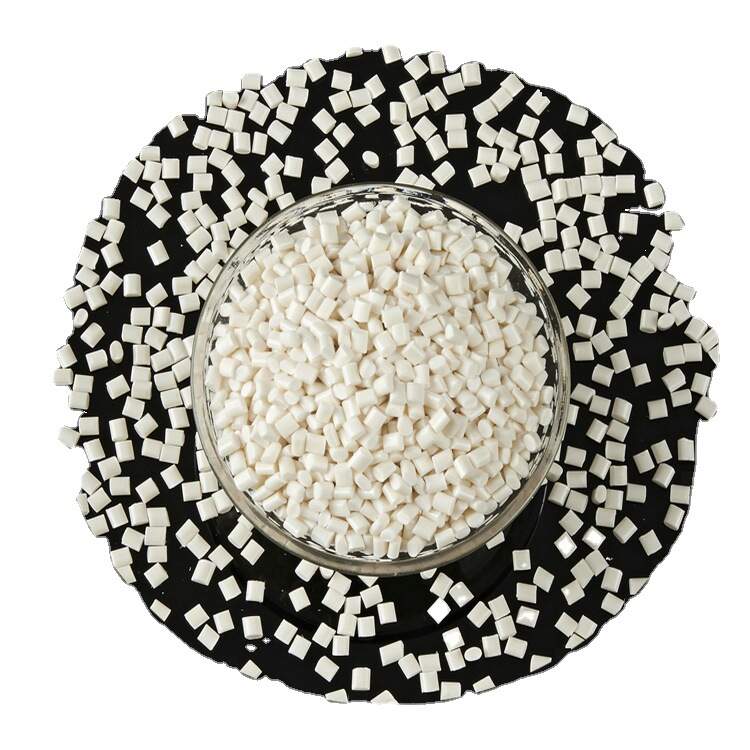

1. What is Flame Retardant ABS?

ABS is a widely used engineering thermoplastic known for its strength, rigidity, and excellent processability. However, standard ABS is inherently flammable and does not meet the fire safety demands of many applications. By incorporating flame retardant additives — such as halogen-based, phosphorus-nitrogen, or halogen-free systems — ABS can be modified to comply with stringent flame retardancy standards like UL 94 V-0.

Flame retardant ABS formulations typically fall into the following categories:

-

Halogen-based systems: Efficient flame retardancy through bromine-antimony synergism.

-

Halogen-free systems: Environmentally friendly phosphorus-nitrogen based formulations.

-

Alloyed or reinforced systems: For enhanced heat resistance or impact strength.

Customers can select the system best suited to their balance of flame retardancy, environmental compliance, mechanical performance, and cost.

2. Flame Retardant Mechanisms and Formulation Characteristics

| System Type | Advantages | Limitations |

|---|---|---|

| Halogen-based | High flame retardant efficiency, easy V-0 certification | Generates smoke and toxic gases; environmental concerns |

| Halogen-free | Low smoke, non-toxic, environmentally compliant | Higher additive load; potential impact on flow and thermal stability |

| Alloyed/Reinforced | Improved heat resistance and dimensional stability | Higher cost |

3. Typical Performance Characteristics

Flame retardant ABS must balance fire resistance with mechanical strength, thermal stability, electrical insulation, and processability. Typical performance ranges are as follows:

Flame Retardancy

-

Meets UL 94 V-0 rating at thicknesses of 1.5 mm and above; some grades achieve V-0 at 0.8 mm or thinner.

-

Available in halogenated and halogen-free formulations compliant with RoHS, REACH, IEC 60695 standards.

-

Exhibits strong char formation and minimal dripping during combustion.

Mechanical Properties

-

Tensile Strength: 40–55 MPa

-

Flexural Strength: 70–90 MPa

-

Notched Impact Strength (23°C): 15–20 kJ/m²

Maintains structural integrity and impact resistance suitable for demanding consumer electronics and automotive parts.

Thermal Properties

-

Heat Distortion Temperature (HDT, 1.8 MPa): 85–105°C

-

Vicat Softening Point: 95–110°C

Suitable for typical electrical housings and structural components; higher heat resistant grades available for automotive electronics and lighting fixtures.

Melt Flow and Processability

-

Melt Flow Rate (MFR, 220°C/10kg): 8–15 g/10 min

-

Standard and high-flow grades are available to accommodate complex thin-wall injection molding and improve mold filling and cycle times.

Electrical Properties

-

Dielectric Strength: ≥15 kV/mm

-

Comparative Tracking Index (CTI): ≥250 V

Excellent insulation properties ensure suitability for electrical device housings, terminal blocks, and connectors.

4. Typical Applications

Flame retardant ABS is widely applied across:

-

Consumer Electronics: TV rear covers, speaker panels, printers, monitors

-

Household Appliances: Rice cooker housings, air conditioner vents, washing machine control panels, vacuum cleaners

-

Electrical Devices: Power sockets, junction boxes, meter housings, terminal modules

-

Automotive Electronics: In-vehicle displays, HVAC panel components, instrument cluster internal parts

-

Smart Devices: Security systems, smart plugs, smart switches, robotics housings

5. Selection Guidelines and Customization Support

When selecting flame retardant ABS, consider the following key factors:

| Key Factor | Considerations |

|---|---|

| Required Flame Retardant Level | Confirm UL rating and test thickness (commonly V-0 @ 1.5 mm) |

| Environmental Compliance | For EU/US markets, halogen-free options recommended |

| Processing Method & Complexity | High flow grades recommended for complex thin-wall parts |

| Mechanical and Thermal Demands | Consider reinforced or alloyed grades for higher heat or load requirements |

| Cost and Supply Stability | Balance performance with budget and supplier reliability |

Our company offers a wide range of flame retardant ABS grades including halogenated, halogen-free, high flow, high heat resistance, and low warp options. We provide formulation optimization and custom development services tailored to your product’s performance requirements and processing conditions. Comprehensive TDS, UL certification details, environmental compliance reports, and samples are available to support your project.

For detailed product specifications, sample requests, or technical consultation, please contact our technical support team. We are committed to delivering the ideal flame retardant ABS solutions for your applications.