Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

High Impact, Flame Retardant, High Strength, UV Resistant ABS Material: A Versatile Engineering Solution

In today’s fast-evolving manufacturing landscape, engineering plastics must meet increasingly stringent requirements—not only in terms of strength, but also fire safety, environmental resistance, and long-term durability.

For industries such as electronics, outdoor equipment, automotive, and lighting, a material that combines high impact resistance, flame retardancy, high mechanical strength, and UV resistance is often essential.

In this blog post, we’ll take a deep dive into the features, benefits, and typical applications of high-performance modified ABS plastic, and how it can help you meet demanding performance and safety standards.

What Is High-Performance Modified ABS Plastic?

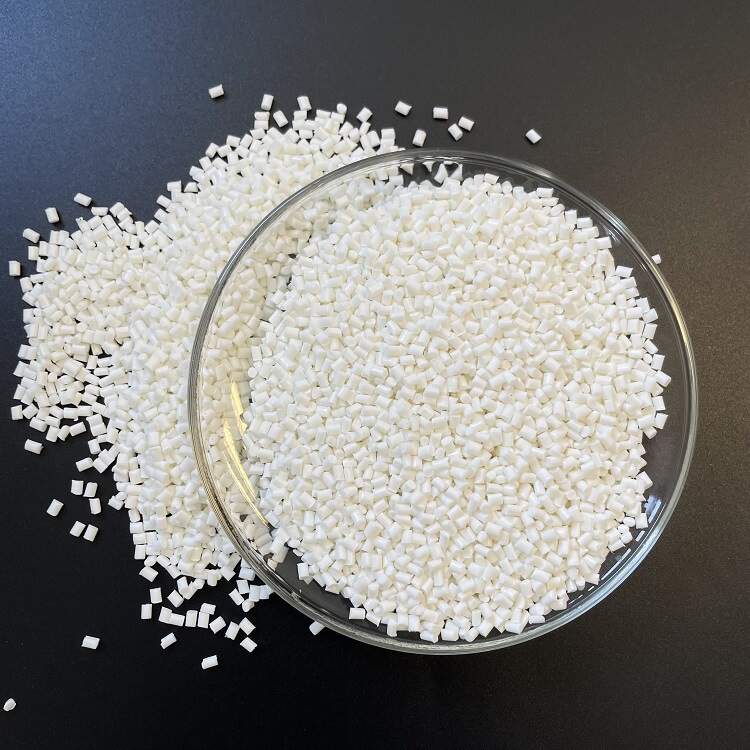

ABS (Acrylonitrile-Butadiene-Styrene) is a widely used thermoplastic polymer known for its good balance of toughness, rigidity, and ease of processing.

Through customized modification and compounding, ABS can be engineered to achieve:

-

Enhanced impact strength

-

Flame retardant capability

-

Improved mechanical strength

-

UV resistance for outdoor use

This makes modified ABS an ideal material for use in demanding environments that require multiple functional properties.

Key Performance Features

High Impact Resistance

-

The material is toughened using elastomers or rubber phase modifiers (e.g., MBS, SEBS), greatly increasing its energy absorption upon impact.

-

Notched Izod impact strength can reach >20 KJ/m², even at sub-zero temperatures.

-

Ideal for protective housings, outdoor components, and vehicle interiors exposed to vibration or accidental drops.

Flame Retardancy (UL94 Certified)

-

Available in flame retardant grades that meet UL94 V-0, V-2, or HB standards, suitable for electronic and electrical applications.

-

Can be formulated with halogenated or halogen-free FR systems to meet RoHS, REACH, and environmental safety requirements.

-

Offers excellent thermal stability and consistent performance during processing.

High Mechanical Strength

-

Reinforced with fillers or structural polymers to increase tensile, flexural, and compressive strength.

-

Tensile strength can reach 50–65 MPa, with low shrinkage and good dimensional stability.

-

Resistant to creep deformation, suitable for structural and load-bearing parts.

UV Resistance for Outdoor Use

-

Formulated with UV stabilizers and antioxidants to prevent yellowing, chalking, or cracking from long-term UV exposure.

-

Ideal for outdoor equipment, solar energy systems, enclosures, and lighting fixtures.

-

Tested to withstand 2–5 years of outdoor aging without significant degradation.

Typical Applications

| Industry | Application Examples | Key Requirements |

|---|---|---|

| Electronics | Power sockets, meter boxes, battery enclosures | Flame retardant, strength, heat resistance |

| Outdoor Equipment | Solar inverters, surveillance cameras, smart boxes | UV resistance, water resistance, weatherability |

| Automotive | Dashboard panels, brackets, interior trims | Impact resistance, light weight, long service life |

| Appliances | Water heaters, air conditioner covers, chargers | Flame resistance, aesthetic surface, toughness |

| Lighting & Building | LED lamp covers, cable housings, wall panels | Weatherproof, fire safety, strength |

Customizable Material Options

We offer tailored ABS formulations to meet your exact needs:

| Custom Feature | Options Available |

|---|---|

| Flame Retardant Grade | UL94 V-0, V-2, HB |

| Color Matching | Natural, black, gray, or Pantone/RAL custom colors |

| Surface Finish | Glossy, matte, electroplating grade, sprayable |

| Processing Compatibility | Injection molding, extrusion, 3D printing |

| Regulatory Compliance | RoHS, REACH, PAHs, halogen-free |

Why Choose Our High-Performance ABS?

-

Reliable Factory Supply: 5 production lines, high monthly capacity

-

Experienced R&D Team: Support for formula customization

-

Comprehensive Technical Support: TDS, MSDS, ROHS available

-

Fast Sample Delivery: Samples can be shipped within 2–3 days

-

After-Sales & Application Guidance: Full technical support for your team

Request a Free Sample or Quote

If you're looking for a material that delivers impact strength, flame resistance, UV stability, and mechanical durability, our modified ABS compound may be the ideal choice.

Contact us today to receive a free sample, technical datasheet (TDS), or to discuss a custom formulation for your project.