Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Deciphering the Phenomenon: Why High Elongation at Break Occurs During Testing

Introduction

When evaluating the properties of polymer blends, the performance in terms of elongation at break is a critical factor to consider. In the case of PP (Polypropylene) and EPDM (Ethylene Propylene Diene Monomer) blends, there are several potential reasons that contribute to their ability to exhibit higher elongation at break compared to normal circumstances. By exploring these factors, we can gain valuable insights into the enhanced mechanical properties and performance of PP and EPDM blends.

There are several potential reasons to consider why PP and EPDM blends may exhibit higher performance in terms of elongation at break.

1. Firstly, it should be noted that the data provided on the TDS (technical data sheet) represents typical values, not guaranteed values. Actual test results may vary due to factors such as mold design, gate type and number, injection molding process parameters, and differences in part thickness, which may lead to fluctuations in test results.

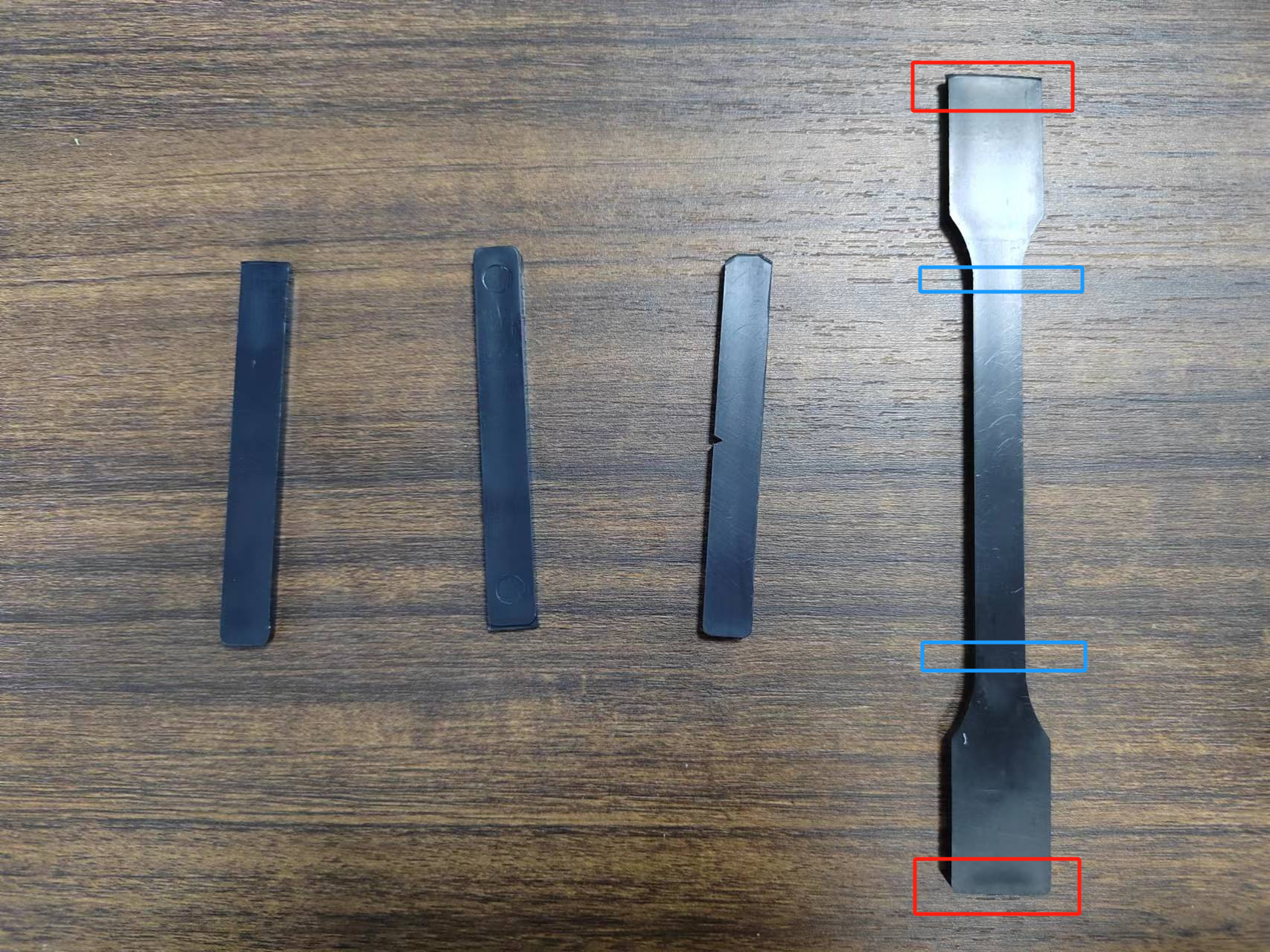

2. During the test bar injection molding process, if the spline mold is small, the EPDM content in certain plastic particles may be locally high. This can significantly enhance the tensile properties of the material, ultimately resulting in increased elongation, which is less common in mass production scenarios.

3. Moreover, data from tensile tests conducted after prolonged storage periods often appear to be higher than the actual values. This could be attributed to the gradual increase in crystallinity of the PP material over time. Therefore, the potential impact of storage duration on test results must be taken into account when evaluating material performance.

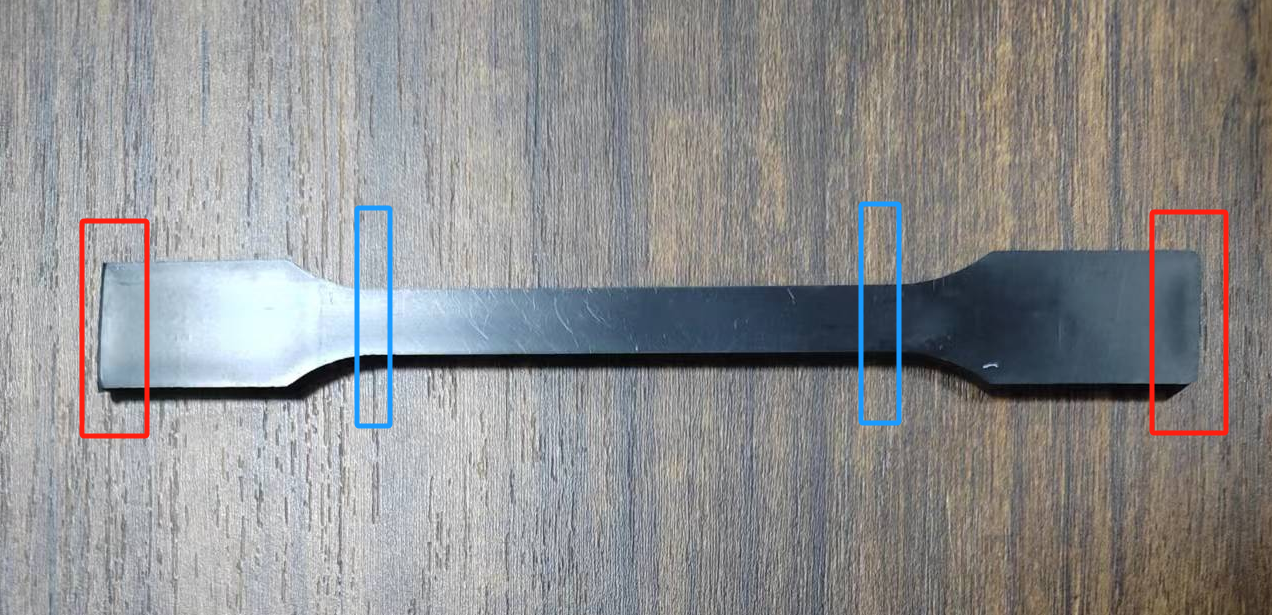

4. Lastly, another reason for higher elongation at break may be associated with the testing method employed. If an extender is not utilized during testing, errors in the test data may occur. Typically, the extender should be clamped in the middle of the spline for accurate testing; clamping at other locations could result in measured data that is higher than half of the actual value.

Therefore, it is vital to assess the elongation at break of PP and EPDM mixtures by considering various factors comprehensively, including mold design, injection molding process parameters, part thickness, storage duration, and testing methods. Only by having a comprehensive understanding and control of the various potential influencing factors can accurate and reliable test results be achieved, offering effective reference and guidance for the production process.