Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

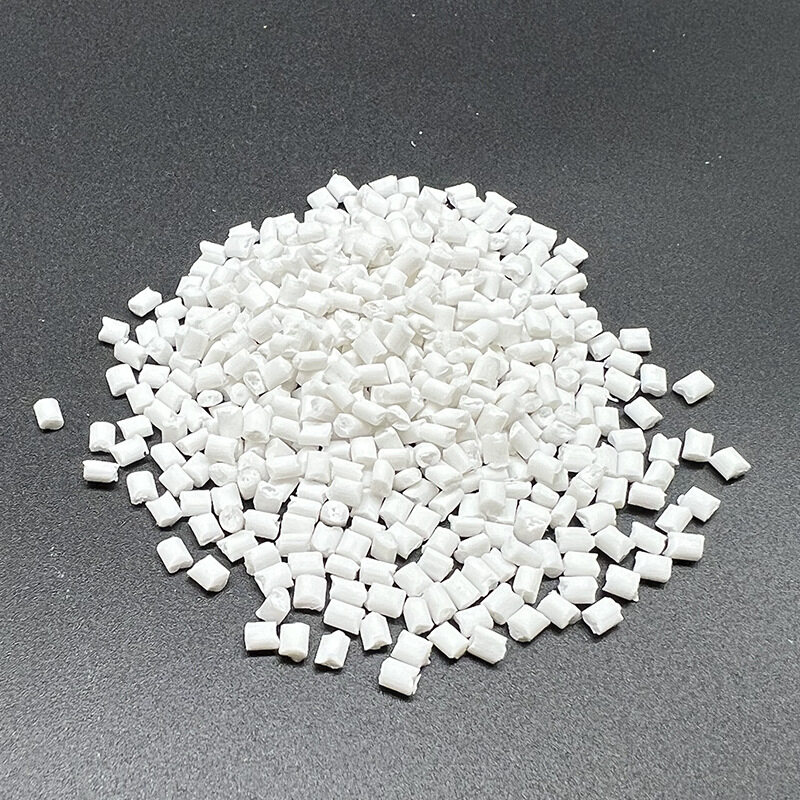

Plastic pellets manufacturers offer a range of innovative solutions for engineering plastic products. They manufacture high-quality pellets from a variety of materials including polyethylene, polypropylene, polycarbonate, and ABS, among others. The pellets come in a variety of sizes and shapes and can be used to create a wide range of products. They are available in bulk or can be custom-made to meet specific needs.

Wholesale plastic pellets are available in a wide range of sizes and shapes, making them ideal for a variety of applications. They are easy to work with and can be molded, extruded, or formed into any shape or size.

Buy plastic pellets in bulk to save money and get the best quality available. Bulk orders are often more cost-effective than buying individual pellets. Bulk orders also offer the convenience of having all the materials you need in one place.

Plastic pellets wholesale are an excellent choice for a variety of projects. They are durable, lightweight, and easy to work with. They are also cost-effective and can be used for a variety of applications. Wholesale plastic pellets are available in a wide range of sizes and shapes, making them ideal for large-scale projects.

Plastic Masterbatch

(7)Black Masterbatch TP-1045BK

TP-1045BK Anti-floating Fiber Organic Black Masterbatch is specially designed for glass fiber reinforced engineering plastics to resist glass fiber surface exposure, and can be compatible with most engineering plastics, such as: PA6, PA66, PPA, PBT , PET, PPS, etc. .

Flame Retardant Masterbatch TP-MPA1007

Halogen-free PA6, PA66 Flame Retardant Masterbatch

Flame Retardant Masterbatch PA-2015FR

PA-205FR is a special halogen-free flame-retardant masterbatch for flame-retardant reinforced nylon . It is a high-efficiency phosphorus-nitrogen flame-retardant masterbatch based on aluminum diethyl hypophosphite (ADP) flame retardant and compounded with phosphorus-nitrogen carbon forming system. The flame retardant powder is coated with functional group compounds through special chemical reaction surface modification, which improves the processing thermal stability and dispersibility of the flame retardant; at the same time improves the physical and mechanical properties of flame retardant reinforced nylon products, especially It is flame retardant and enhances the moisture and heat aging resistance of nylon products. The masterbatch of halogen-free flame retardants has enlarged the processing window of halogen-free flame-retardant reinforced nylon, making it easier to produce flame-retardant reinforced nylon products, and at the same time reducing the risk of powder dust.

Flame Retardant Masterbatch ADP-502FR

ADP-502FR halogen-free flame retardant masterbatch is a masterbatch made of aluminum diethyl hypophosphite (ADP) flame retardant powder, which is made of functional group compounds after special chemical reaction surface modification and coating treatment. Improve the processing thermal stability and dispersibility of ADP flame retardant; at the same time improve the physical and mechanical properties of flame retardant products, especially the moisture and heat aging resistance of products. The masterbatch of halogen-free flame retardants increases the processing window of ADP flame retardants, making the use of ADP flame retardants more convenient and reducing the risk of powder dust.