Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Flame Retardant Masterbatch TP-MLS802C

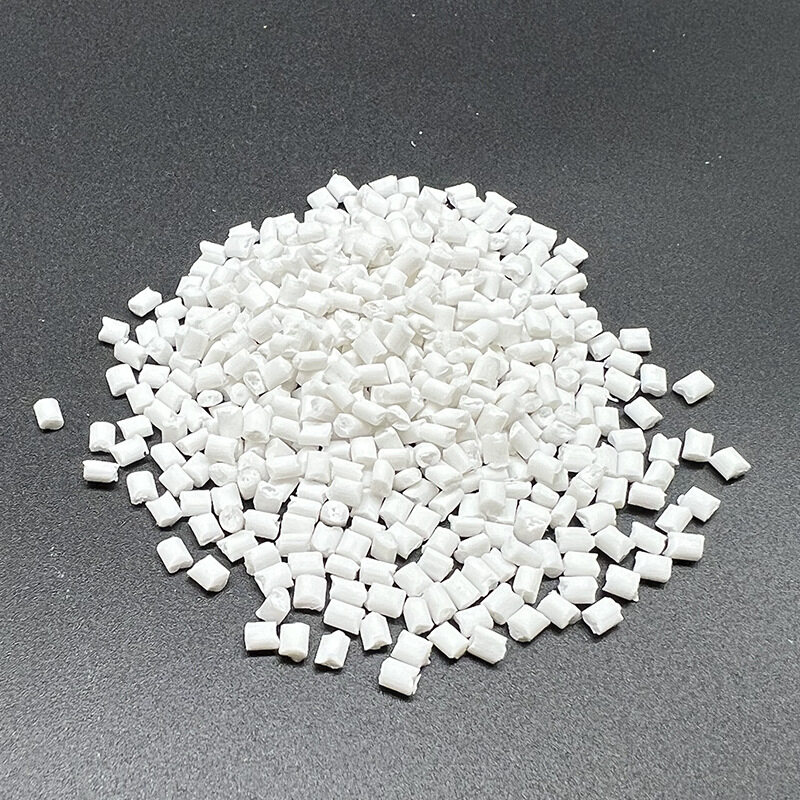

TP-MLS802C is a flame-retardant masterbatch prepared with decabromodiphenylethane and high-purity antimony trioxide (99.8%) as the main raw materials, supplemented with flame-retardant synergists and other additives, and polyolefin as the carrier. It is easy to use , good dispersibility, the product fully complies with Reach, RoHS and other relevant environmental laws and regulations. TP-MLS802C flame retardant masterbatch is especially suitable for blow molding, cast film, drawing, wire, pipe and other thin products of polyolefin materials.

- Product Details

-

Download

TP-MLS802C Environmental Flame Retardant Masterbatch

TP-MLS802C is a flame-retardant masterbatch prepared with decabromodiphenylethane and high-purity antimony trioxide (99.8%) as the main raw materials, supplemented with flame-retardant synergists and other additives, and polyolefin as the carrier. It is easy to use , good dispersibility, the product fully complies with Reach, RoHS and other relevant environmental laws and regulations. TP-MLS802C flame retardant masterbatch is especially suitable for blow molding, cast film, drawing, wire, pipe and other thin products of polyolefin materials.

Product physical index

|

Project |

Index |

|

Appearance |

white cylindrical particles |

|

Density |

≥2.0 g/cm3 |

|

Moisture and volatile matter content |

≤0.3 % |

|

Melt index (190°C, 2. 16Kg) |

7.0 g/10min |

Product Features

1. TP-MLS802C has good compatibility with the substrate, and the surface of the workpiece is smooth and clean, without melting and white marks issues;

2. It can be directly mixed with resin for extrusion and injection molding, reducing dust pollution;

3. Avoiding defects such as uneven feeding, low output, and unstable product performance caused by the use of powder;

4. Fully comply with RoHS and other relevant environmental protection laws and EU REACH regulations.

Storage and Transportation

1. The net weight of each package of this product is 25kg, and it is transported as an ordinary chemical.

2. The product should be stored in a dry and ventilated warehouse.

1 、LDPE 8-12%

2 、HDPE 12-15%

Download

-

TP-MLS802C Environmental Flame Retardant Masterbatch.pdf